Product Description

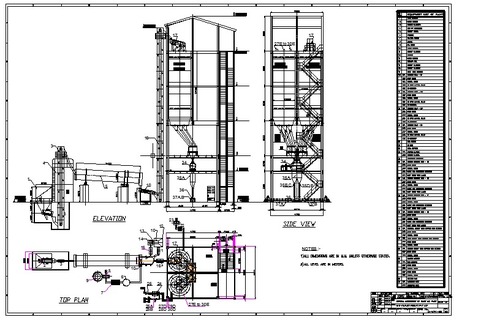

Ready Mix Plaster Plant Our company timely delivers this Ready Mix Plaster Plant across the world. This easy to install plant is mainly utilized to process clay, cement, gypsum, lime hydrate and other minerals for making plaster. The assembly of this plant is performed by our experts using advanced techniques and quality-tested components. Customers can even get this Ready Mix Plaster Plant in specifications that suit their application requirements. Under computerized fully and semi - automatic batch process, ready mix plant is manufactured in modern dry mix plant. This plaster can be used by mixing water at site. This process doesnt requires job site mixing practices, which is why gives consistent quality along with desired size of sand mesh in appropriate proportion. This is important for plasters compactness. Effective and cost efficient way for lime calcinations.What is Plastering The process of plastering is carried out to cover rough surface of columns, walls, ceilings and other building parts with thin coat to form a surface which is hard, smooth and durable, capable of protecting external surface from penetration of rain water as well as other atmospheric vagaries. It is important that plaster has strong adhesion on ceilings and walls with crack free properties and resistance against water. These properties protect interior surface and give flat base for painting. It is useful in speeding up the construction work and minimizing the maintenance inconvenience. Plastering is as important as brick work, structural members, plumbing, flooring, painting and electrical work. Features & Benefit Plant Type: Semi -automatic & fully automaticPlant Capacity : 2.5, 5 10, 20Mt/HrSave time as it is easy to useMinimizes rebounding, No sit content.Ready mix plaster gives highly durable plaster that minimizes repair and maintenance cost.Good workability and adhesion on several substrate, compact plaster, reduces void gapsPaint finish and life of paint are enhancedIdeal for several surface IE Bricks, walls and blockProduct apt for internal as well as external wall. Benefits Factory Made And Pre Packed Premixed MaterialsExcellent Workability & Little Rebounding Losses Give To Suitable Imported Polymers.Less Storage Space, No Sieving Cost At Site, No Silts, No Singles, No Disposal Cost, No ShiftingCost For Several Ingredients, Therefore Saving In Indirect Cost & Overall Cost EffectiveMaterial Effective In High Rise BuildingsCement Sand Ratio - Sand Cement Ratio Is Achieved As RIVIP Is Manufactured In Automated PlantPlaster Thickness - Can Be Reduced Upto 25% Keeping The Desired Strength.Polymer Modification - Polymers Already Added Results In Overall Durability.

FAQs of Ready Mix Plaster Plant:

Q: What is the capacity of the Ready Mix Plaster Plant?

A: The Ready Mix Plaster Plant has a capacity of 10 T/hr.

Q: What is the warranty period for the Ready Mix Plaster Plant?

A: The warranty period for the Ready Mix Plaster Plant is 2 years.

Q: Does the Ready Mix Plaster Plant come with an automatic control system?

A: No, the Ready Mix Plaster Plant is not automatic; it operates under PLC control.

Q: What is the power specification of the Ready Mix Plaster Plant?

A: The Ready Mix Plaster Plant has a power specification of 100 Horsepower (HP).

Q: What is the material used for constructing the Ready Mix Plaster Plant?

A: The Ready Mix Plaster Plant is constructed from cast iron and steel.

Q: What is the voltage requirement of the Ready Mix Plaster Plant?

A: The Ready Mix Plaster Plant requires a voltage of 80 Volt (v).

Q: Does the Ready Mix Plaster Plant include computerized operations?

A: Yes, the Ready Mix Plaster Plant supports computerized operations.